Mining surveys are the backbone of every successful operation. Yet for many teams, they’re also a source of constant pressure. The demand for precision data in harsh, unpredictable environments is immense. Surveyors and mining engineers often work against time, facing tight schedules, complex underground conditions, and, above all, safety risks.

From uneven terrain and unstable ground to limited visibility and restricted access, the challenges of mine surveying go far beyond typical project constraints. Mistakes are costly – not only in financial terms, but also in terms of human safety.

That’s why many forward-thinking mining companies are turning to 3D scanning for resource industry projects – a smarter, faster, and safer way to capture accurate spatial data.

Table of Contents

What Is 3D Laser Scanning and Why Is It Changing Mining Surveys?

3D laser scanning is revolutionising the way mining data is captured, interpreted, and shared. Instead of relying solely on manual measurements and line-of-sight techniques, surveyors can now use laser scanners to collect millions of precise data points in just minutes.

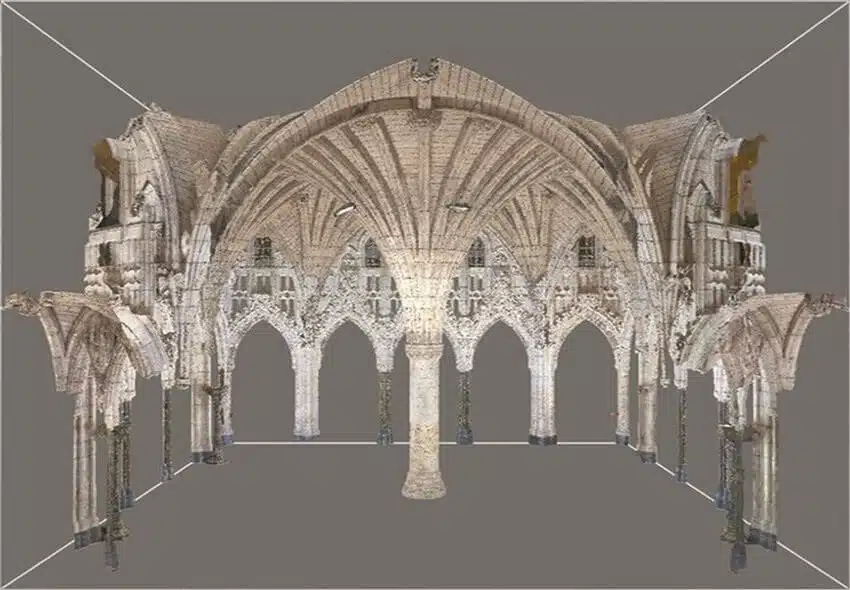

The result? A detailed 3D digital twin, known as a point cloud, that accurately represents the mine environment, both above and below ground.

Traditional Survey Challenges in Mining

Before laser technology, mining surveys were often limited by:

- Physical risks to personnel – entering hazardous zones to take manual readings.

- Downtime during data collection – halting operations while surveys were carried out.

- Incomplete or error-prone measurements – caused by poor visibility, restricted access, or human limitations.

3D laser scanning eliminates many of these challenges, capturing comprehensive data without needing anyone to step foot into unsafe areas.

How Does 3D Laser Scanning Work in Mining?

3D laser scanning works by emitting pulses of light that bounce off surrounding surfaces and return to the sensor. The scanner measures the time it takes for each pulse to return, calculating exact distances and forming a dense cloud of data points that represents the scanned area in three dimensions.

What Does the Process Look Like Underground?

- Equipment Setup – Lightweight scanners are positioned in strategic locations, sometimes mounted on tripods or mobile rigs.

- Remote or Automated Data Capture – Scanners operate without requiring people to remain in hazardous zones.

- No-Contact Surveying – Laser beams measure distances with no need for physical contact or interference with equipment.

- Generation of Point Clouds – Millions of measurements are processed into a digital twin for analysis and decision-making.

These high-resolution scans can then be integrated with Building Information Modelling (BIM) services and other digital tools, helping mine planners visualise conditions with exceptional clarity and insight.

What Is 3D Laser Scanning and Why Is It Changing Mining Surveys?

3D laser scanning is revolutionising the way mining data is captured, interpreted, and shared. Instead of relying solely on manual measurements and line-of-sight techniques, surveyors can now use laser scanners to collect millions of precise data points in just minutes.

The result? A detailed 3D digital twin, known as a point cloud, that accurately represents the mine environment, both above and below ground.

Traditional Survey Challenges in Mining

Before laser technology, mining surveys were often limited by:

- Physical risks to personnel – entering hazardous zones to take manual readings.

- Downtime during data collection – halting operations while surveys were carried out.

- Incomplete or error-prone measurements – caused by poor visibility, restricted access, or human limitations.

3D laser scanning eliminates many of these challenges, capturing comprehensive data without needing anyone to step foot into unsafe areas.

How Does 3D Laser Scanning Work in Mining?

3D laser scanning works by emitting pulses of light that bounce off surrounding surfaces and return to the sensor. The scanner measures the time it takes for each pulse to return, calculating exact distances and forming a dense cloud of data points that represents the scanned area in three dimensions.

What Does the Process Look Like Underground?

- Equipment Setup – Lightweight scanners are positioned in strategic locations, sometimes mounted on tripods or mobile rigs.

- Remote or Automated Data Capture – Scanners operate without requiring people to remain in hazardous zones.

- No-Contact Surveying – Laser beams measure distances with no need for physical contact or interference with equipment.

- Generation of Point Clouds – Millions of measurements are processed into a digital twin for analysis and decision-making.

These high-resolution scans can then be integrated with Building Information Modelling (BIM) services and other digital tools, helping mine planners visualise conditions with exceptional clarity and insight.

Why Is 3D Laser Scanning More Accurate and Efficient Than Older Survey Methods?

Traditional surveying relied heavily on manual input, which introduced variables that could easily lead to errors or missed details. By contrast, 3D scanning delivers data that is not only more comprehensive but also ten times faster to capture.

Key advantages of modern laser scanning over traditional surveying methods include

- Rapid data acquisition – Capture vast areas in minutes, reducing time on-site.

- Unmatched precision – Achieve millimetre-level accuracy for tunnels, shafts, and stockpiles.

- Revisit digital models anytime – Analyse data without needing to return to the site.

- Integrated workflows – Combine scans with CAD and GIS platforms for seamless planning.

For mining operations where every hour counts, the ability to collect, analyse, and act on data faster translates to lower costs and greater efficiency.

How Does 3D Laser Scanning Make Mining Surveys Safer?

Safety is one of the most compelling reasons why the benefits of 3D laser scanning in mining are being embraced by operators across Australia. By drastically reducing the need for personnel to enter high-risk environments, laser scanning helps ensure worker well-being without compromising on accuracy.

How Is Surveyor Safety Improved?

- Remote mapping minimises worker exposure – Scanners can operate safely from a distance, even in unstable areas.

- Early detection of structural weaknesses – Identify potential hazards before they become serious risks.

- Real-time ground stability monitoring – Detects movement or deformation as it happens, improving response times.

By removing the need for physical entry into confined or unstable spaces, 3D scanning provides a safer alternative that still meets (and often exceeds) traditional surveying standards. It’s a prime example of how 3D scanning improves mine safety and overall operational resilience.

What Are the Practical Benefits for Mining Companies?

The true impact and benefits of 3D laser scanning in mining go beyond speed and safety. The technology gives mining companies a digital twin of their site, improving operational intelligence and enabling data-driven decisions from exploration to rehabilitation.

The most significant benefits include

- Reduced downtime – Quicker surveys mean less interruption to production schedules.

- Cost efficiency – Accurate data supports better planning and reduces rework.

- Improved project visibility – Data can be shared with engineers, regulators, and stakeholders instantly.

- Sustainable site management – Detailed 3D records support compliance, monitoring, and reclamation efforts.

- Enhanced planning and design – Generated 3D Models integrate seamlessly with architectural and engineering software.

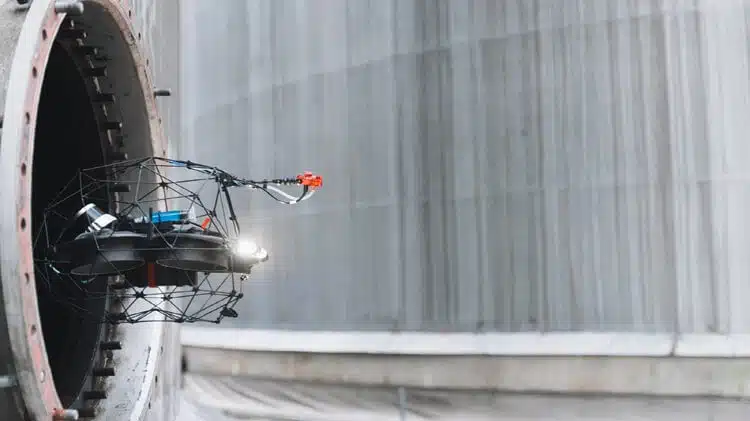

When combined with drone surveying and mapping solutions, these scans offer even broader visibility across vast mining landscapes, from open-pit operations to deep underground networks.

Laser Scanning and Data Intelligence – Building the Mines of the Future

The mining industry is evolving, and those leading the change are those investing in smarter data. With ongoing advances in laser scanning technical concepts, mine operators now have the tools to model, monitor, and manage sites with unprecedented clarity. Point cloud data can even be integrated into planning software, allowing virtual walk-throughs, deformation tracking, and predictive maintenance – a key example of how point clouds transform project workflows. For the resources industry, the message is clear: the future of surveying is digital, precise, and safe.Expert Mining Surveyors Making 3D Scanning Work for You

At Avian, we understand the precision and safety demands that come with mining surveys. Our experienced team specialises in professional 3D laser scanning services tailored to the unique challenges of the resources sector. Whether you’re mapping an underground shaft, assessing slope stability, or planning site expansion, we deliver data-driven insights that help you make smarter, faster, and safer decisions.How Can Avian Help Your Mining Project?

Our mining-focused scanning solutions include- High-accuracy point cloud generation for underground and surface environments.

- Integration with existing design software, including AutoCAD, Revit, and GIS systems.

- Customised reporting and 3D visualisation, simplifying data interpretation for teams and stakeholders.

- Support for major infrastructure and heritage projects, demonstrating our versatility beyond mining.