Our Solutions for Engineering

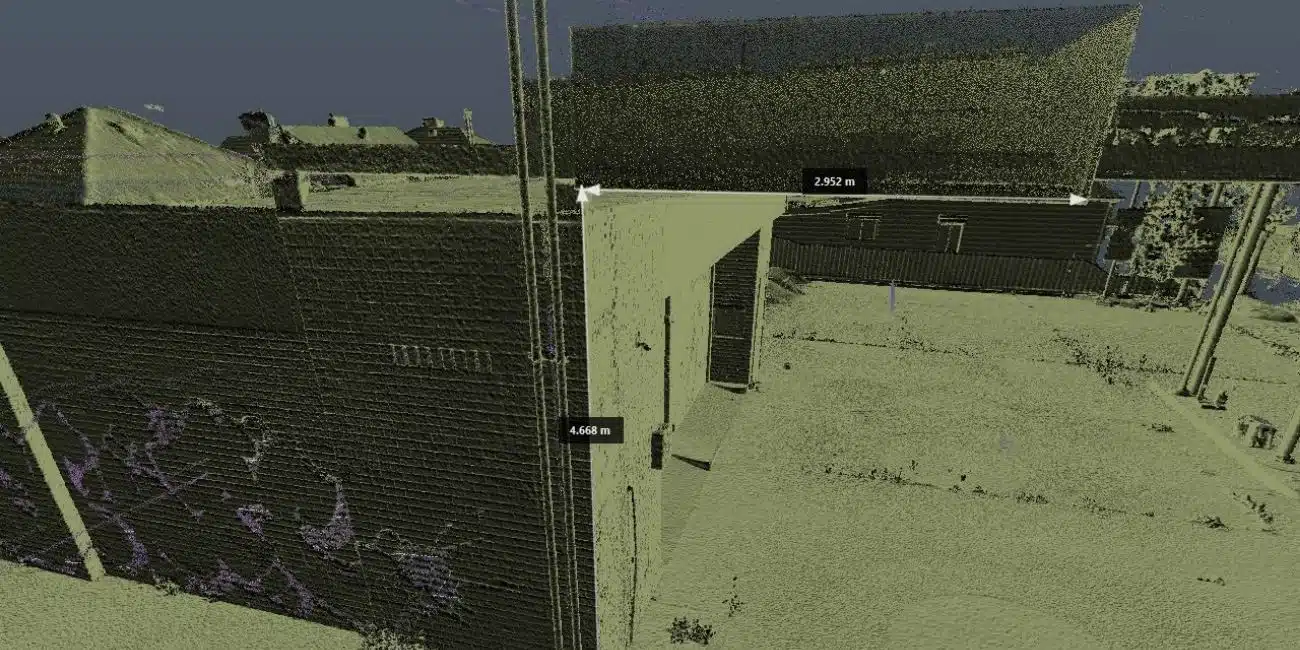

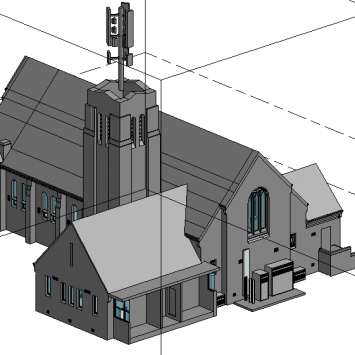

As-Built Documentation

Capture precise, real-time measurements of existing structures, equipment, and facilities to create accurate as-built models for design, retrofitting, or renovation projects, eliminating guesswork and reducing the risk of errors

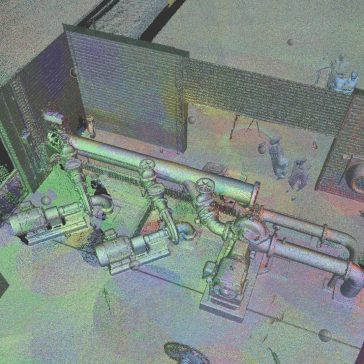

Reverse Engineering

Recreate a digital model of a structure when the original design documentation is missing or outdated using 3D scanning for reverse engineering. Efficiently analyse the scanned data to improve, replicate, or modify components.

Quality Control and Inspection

Use scanned data to compare manufactured parts against design specifications (CAD models) to identify deviations, deformations, or defects with sub-millimetre precision, ensuring product quality and compliance with standards.

Structural Analysis and Simulation

Understand how structures have shifted, deformed, or worn over time. Data from 3D scans feed into simulations (e.g., finite element analysis) to predict stress points, performance under load, or necessary reinforcements.

Clash Detection and Coordination

Use 3D scans in multidisciplinary engineering projects (including mechanical, electrical, and structural) to ensure all systems fit together properly. This is especially useful in complex environments like industrial plants or commercial buildings.

Maintenance and Facility Management

3D laser scanning for engineering can support design and planning by creating a detailed digital twin for tracking changes, planning upgrades, designing and coordinating repairs with minimal disruption.

3D Scanning for Engineering That Delivers Absolute Accuracy When You Need It

Our 3D scanning for engineering services delivers precise capture of every aspect of your project site, supporting accurate planning and execution. Using cutting-edge 3D laser scanning and surveying technology, we gather detailed data for both external and internal structures—including industrial plants, infrastructure, and mechanical systems—positioning us as a leader in engineering survey solutions.

3D laser scanning for engineering provides rapid, accurate documentation of existing conditions, ensuring exact geometry and spatial data for complex engineering environments.

At Avian, we employ advanced 3D laser scanning, surveying, and geospatial techniques to capture as-built conditions with millimetre-level accuracy, empowering engineers with reliable information for design, analysis, and quality control.

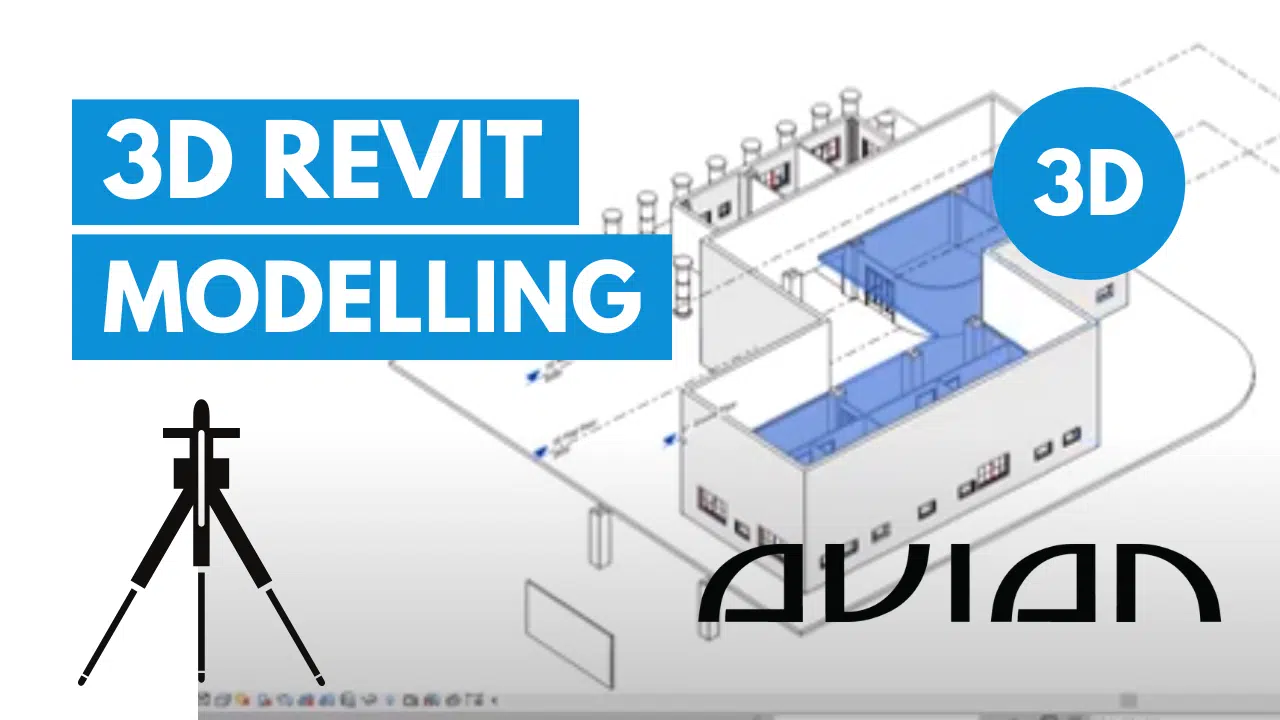

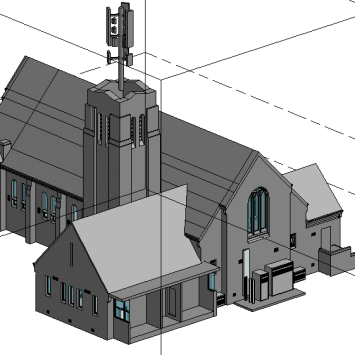

Scan to BIM

Scan to Plan

Scan to Model

Start designing sooner with direct Software Integration

Seamlessly integrate with industry-standard software such as Autodesk Revit, Civil 3D, AutoCAD, Archicad, Solidworks, Microstation, Rhino and Bentley Systems.

Experience immediate integration of scan data for modelling and design applications.

Share and collaborate laser scan data and 3D models with teams, stakeholders and clients via our secure web-based applications.

The Benefits of 3D Laser Scanning for Engineering

Reduce Project Risks and Rework

By using highly accurate 3D scan data, you can avoid costly errors and redesigns, saving time and money while boosting your reputation for delivering reliable results.

Enhance Safety for Your Team

3D scanning reduces the need for engineers and surveyors to access dangerous or hard-to-reach locations, helping your firm maintain a strong safety record, ensure alignment with ISO certifications, and reduce liability.

Lower Operational Costs

Automated scanning means less manual labour and fewer site visits, helping your team cut overhead expenses and increase profitability without sacrificing quality.

Improve Collaboration and Client Confidence

Detailed digital models simplify coordination across disciplines and communication with clients, strengthening relationships and increasing your chances of winning repeat business and new contracts.

Accelerate Project Timelines

Faster data capture helps you move quickly from surveying to design and construction, giving you a competitive edge by delivering projects on or ahead of schedule.

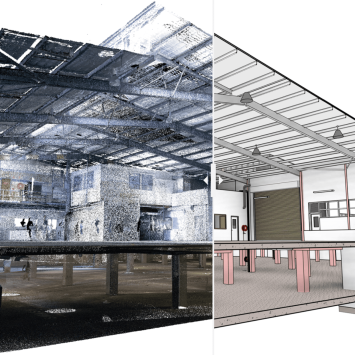

Use Scroll Bar to view Point Cloud Vs The 3D Model

Why Choose Our 3D Scanning for Your Engineering Projects?

Avian is a trusted partner for 3D scanning and laser scanning services in Sydney, Brisbane and Melbourne. We have collaborated with numerous engineering firms on complex commercial and industrial projects.

We focus on leveraging the latest scanning technology, continuous professional development, and strict quality controls to deliver precise and reliable data that supports successful project outcomes.

Enhanced Stakeholder Communication

Provide clear and accurate 3D data that helps engineers, contractors, and clients fully understand project conditions and technical details.

Faster Project Approvals

Our high-quality scan deliverables facilitate quicker decision-making, reducing delays in the approval and planning stages.

Increased Client Confidence

Deliver detailed and accurate visualisations that not only meet but exceed expectations, helping your team secure trust and foster long-term partnerships.

3D scanning for reverse engineering

This is only one of the applications of our scanning technology. We also provide a more holistic, cross-industry approach to projects by offering 3D scanning and laser scanning for architecture and 3D scanning and laser scanning for construction.

100+ CLIENTS

Renders

Visualisations

3D Models

Contact the AVIAN team today to discuss your project

3D Laser Scanning for Engineering FAQs

The cost of 3D scanning varies depending on factors like the size and complexity of the site, the level of detail required, and the type of deliverables – whether point clouds, 3D CAD models, or full BIM outputs. Projects with dense MEP systems or high-accuracy requirements typically involve more processing and higher costs.

We supply data in a range of industry-standard formats, including point clouds (E57, LAS), 2D CAD files (DWG, DXF), and fully developed 3D BIM models (Revit, IFC). Deliverables are tailored to integrate with your existing workflows, whether you’re working in structural design, MEP coordination, or civil planning.

3D scanning captures precise, real-world conditions of existing MEP and structural systems. Engineers use this data to detect potential clashes, improve installation planning, and ensure new components align with existing structures, reducing site delays and costly rework.

Feel free to check out this case study wherein our team conducted a laser scan of a commercial warehouse to understand more about laser scanning.

3D scanning delivers

millimetre accuracy, depending on project requirements. Unlike traditional methods, which rely on selective measurements, 3D laser scanning collects millions of data points in full 3D, providing engineers with a comprehensive, high-resolution dataset for analysis and modelling.

Timeframes depend on project scale, but a typical scan can be completed in one day on site, with processed models delivered within 1–2 weeks. Larger or more complex sites may require more time for data processing, especially when high-detail MEP or structural models are requested.

We follow strict QA protocols at every stage, from initial data capture to final model delivery. Our team uses calibrated, industry-grade scanning equipment and checks data accuracy during acquisition, processing, and output. All deliverables undergo internal review to ensure they meet engineering-grade precision and meet client specifications.