Engineering Efficiency Elevated: Avian Australia's Laser Scanning and Measurement Breakthrough

Introduction

In this case study, we will explore how Avian Australia, a leading digital imaging, surveying, and reality-capture company, partnered with the engineering industry to address the challenges of conducting site assessments, measurements, and analysis efficiently and accurately. Avian Australia’s innovative approach to laser scanning and measurements revolutionized project development and planning in the architecture, engineering, and construction (AEC) sector.

Client Background

Our client, a prominent player in the engineering field, faced a common issue: the need to assess and analyze site features across multiple locations. Traditional site visits often led to travel restrictions, high costs, and significant downtime for staff. This challenge hindered the client’s ability to gather critical information necessary for ongoing project development and planning.

Problem Statement

The problem was evident: the conventional approach to site assessments was burdensome and costly. Travel-related expenses and the disruption caused by site visits created inefficiencies in project management. Furthermore, there was often a disconnect between information shared among project team members and site contractors, leading to duplication of effort, rework, and costly errors.

Avian Australia’s Solution

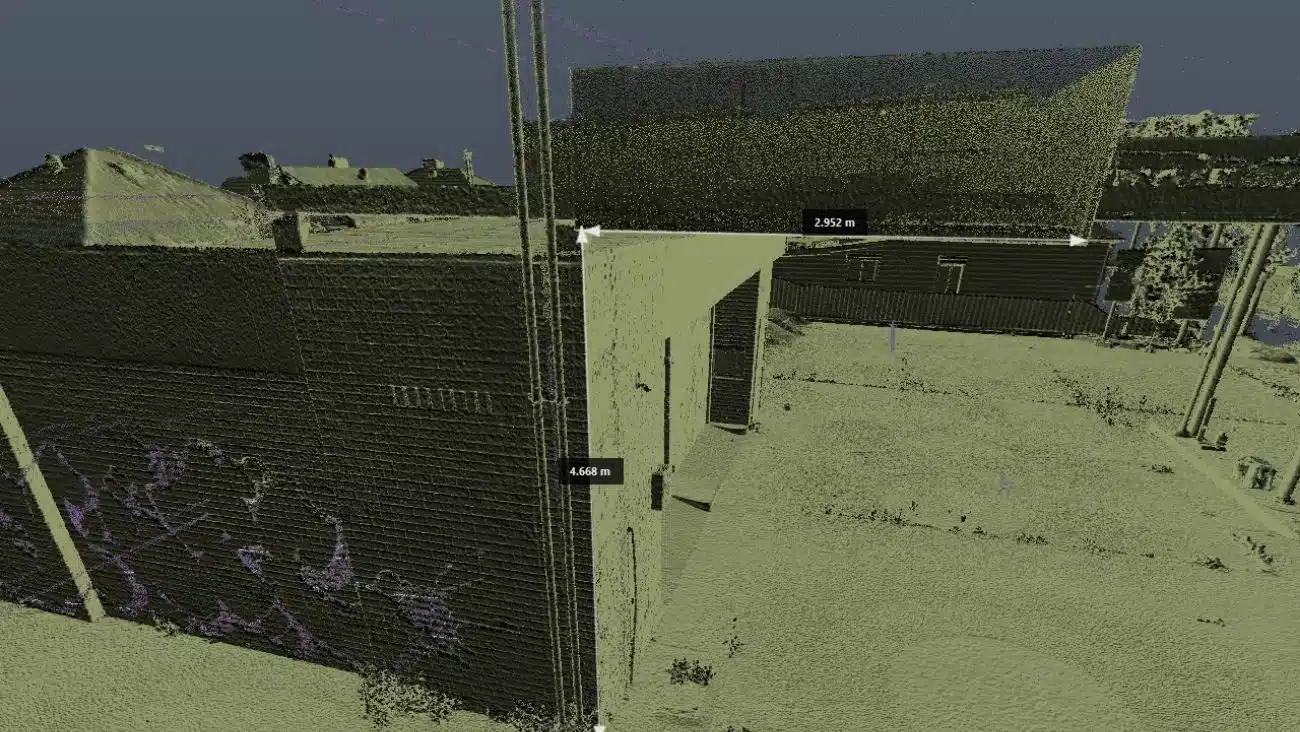

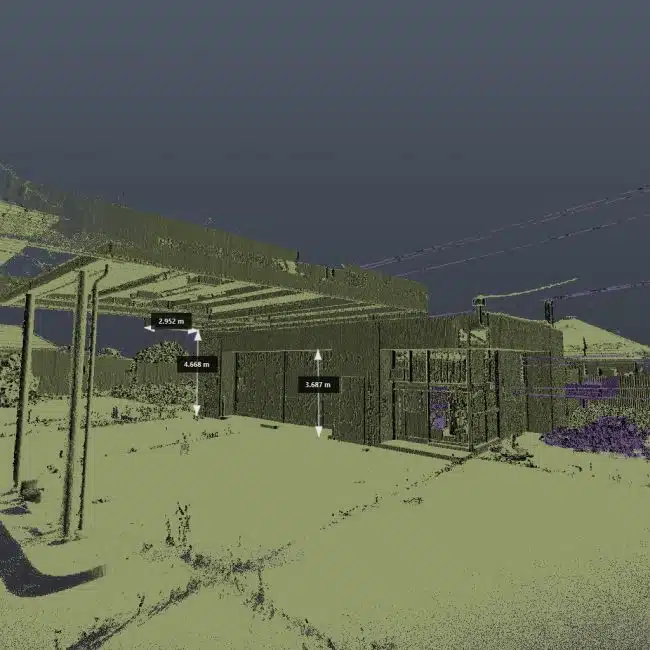

Avian Australia offered a transformative solution by deploying precision surveying, laser scanning, and measurements equipment. Their methodology involved capturing millions of laser point measurements to create a high-precision point cloud. This point cloud was then processed into a 3D model (.rvt), compatible with leading design and drafting software such as Civil 3D, REVIT, CAD, and more.

Avian Australia’s surveying methodology ensured minimal errors and a streamlined workflow for both interior and exterior scanning and modeling. Their data quality assurance process guaranteed the delivery of high-quality, accurate 3D models and 2D drawings to the client.

Implementation

For the specific project involving a petroleum site, Avian Australia utilized a terrestrial laser scanner, a total station, and a professional UAV drone. These tools allowed them to complete the onsite laser scan in just one day. The data collected from these devices were cross-referenced, validated, and integrated during data processing to create a consolidated point cloud. This point cloud served as an accurate 3D digital twin of the site, facilitating design, analysis, and measurements.

Additionally, Avian Australia provided the client with a comprehensive set of photographs and media, enabling a virtual site tour and in-depth site analysis of key features upon request.

Results

The outcomes were highly beneficial:

✓ The entire site was laser scanned and all data collected within a single day, minimizing disruption.

✓ The use of a professional UAV drone allowed for the complete digital twin of roof assets.

✓ The client gained confidence in measuring and analyzing site information from the point cloud and reference materials provided.

✓ Staff were able to focus on their core tasks, and project management continued seamlessly without delays caused by pending site information.

✓ Datasets were archived, ensuring accessibility for future reviews without the need for revisiting the site or gathering additional information.

Choosing the right Laser Scanning Service

At Avian Australia, we offer a range of laser scanning services tailored to meet the specific needs of architects and construction managers. When choosing the right package, consider the scope of your project, the level of detail required, and your budget. Contact us today to discuss your project and receive a customised quote.

Avian Australia Commitment

Avian Australia’s innovative approach to laser scanning and measurements has reshaped the landscape of site assessments and analysis in the engineering industry. By eliminating the inefficiencies and errors associated with traditional site visits, Avian Australia has empowered clients to make informed decisions swiftly and effectively. Their commitment to precision and data quality ensures that digital assets remain invaluable resources for future projects and assessments.