Reduce risk, cost & save time

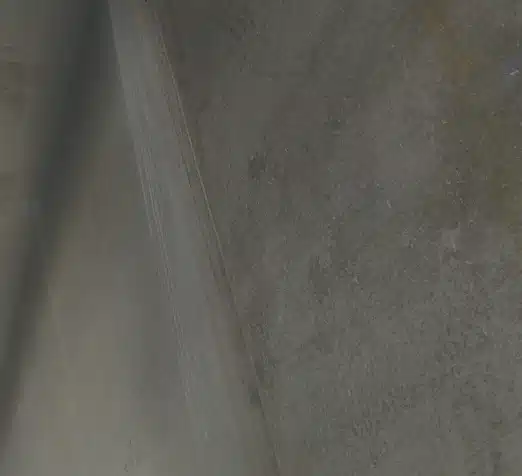

Avoid time consuming and costly methods of inspection and analysis. Conducting a visual inspection in difficult to access positions poses risks to workers and takes time for approvals, job safety permits and often involves costly access equipment. Some confined spaces require additional training and certification to access due to noxious gases or worker hazards that are deemed too high-risk activities.

FAST AND EFFICIENT

Safety

Our remotely operated cameras eliminate the need for people to access confined, dangerous or high-risk locations, dramatically improving the safety of inspections.

Early detection

Due to lower costs and reduced risk, inspections can be made at greater frequencies. This increases the chances of identifying an issue at an earlier stage.

Lower cost of rectification

Early detection allows rectification before greater deterioration takes place. The earlier the issue is identified and fixed, the lower the cost.

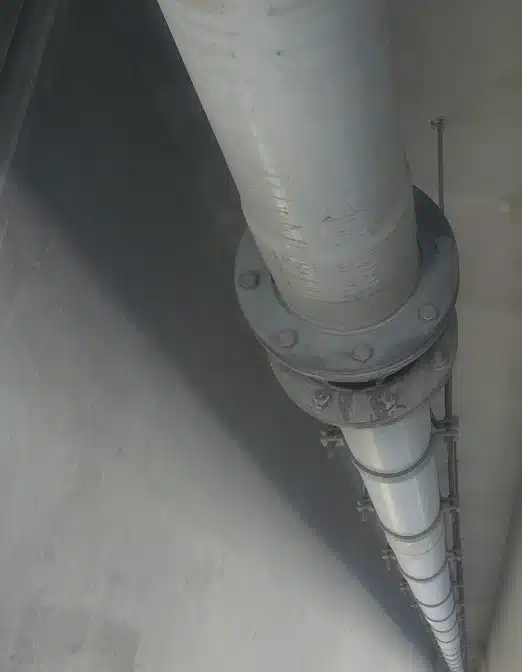

Our high-resolution imaging carried out using aerial UAV cameras allows detailed inspection of difficult to see positions for existing conditions including:

rust, cracking, spalling, flaking, deterioration and water egress.

Automated defect detection

Using high-resolution imaging and 3D laser scanning, we combine data with machine learning to expedite defect detection and analysis. We use a combination of image analysis and defect indexing for a faster asset inspection workflow. Our AI intelligent reporting provides asset classification more efficiently than manually conducting asset inspections and audits.

DRONE INSPECTIONS

Lower cost

Using UAVs to capture high-detail images and video, eliminates the need for engineers to access structures or use access equipment and therefore significantly lowers the cost of inspections. Targeted maintenance and repairs can be planned more effectively as and when the work is needed.

Compliance

When using our aerial asset site and building inspection methods, maintenance programs can meet demanding inspection compliance schedules without significant extra cost.

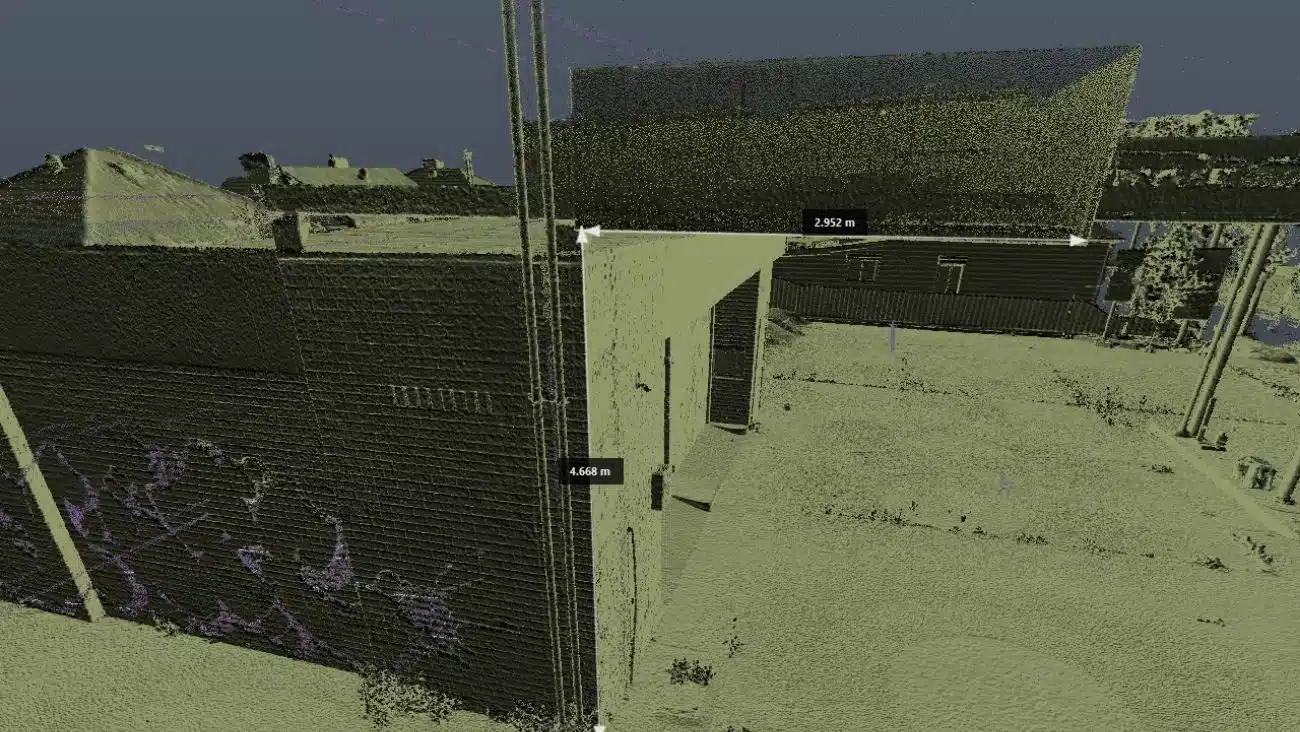

Accurate Measurements

Accurate reconstruction with 3D digital models allows engineers to integrate into CAD, Solidworks and Civil 3D to assess existing conditions and determine the cost of maintenance or rectification works.

Use Scroll Bar to view the Point Cloud Vs The 3D Model

Services Methodology

AVIAN has a proven services methodology for repeatable and reliable data collection and analysis.

Discovery

Identify and define the client context, specific problem, objectives and desired outcomes.

Definition

Determine appropriate staff, equipment, planning, permits and approvals required to capture, process then analyse data to deliver the objectives.

Solution

Proposal to client with fit-for-purpose solution including project management, data capture, analysis and reporting.

Execution

Complete risk assessments, permits, flight plans, safety inductions and approvals. Conduct operation and data capture.

Analysis

Conduct data validation, quality control, data processing, analysis and reporting.

Identify and define the client context, specific problem, objectives and desired outcomes.

Determine appropriate staff, equipment, planning, permits and approvals required to capture, process and analyse data to deliver the objectives.

Proposal to client with fit-for-purpose solution including project management, data capture, analysis and reporting.

Complete risk assessments, permits, flight plans, safety inductions and approvals. Conduct operation and data capture.

Conduct data validation, quality control, data processing, analysis and reporting.

100+ CLIENTS

Speak with the team at AVIAN to discuss your project needs. We love to solve complex problems using our combined knowledge and experience so let us know more about yours.

FAQs about Aerial Asset Inspections using Drones

We have answered some common questions that clients have about aerial asset inspections for engineering.

Depending on the size and scope of work, it takes about one to two days to inspect a bridge using our imaging equipment, including drones. Our enterprise drones allow us to maneuver into difficult-to-access positions over water, underneath bridges and at heights. We can capture high detail images and video using 30x zoom cameras and LED lighting to illuminate darker areas.

Also, at Avian, we have a team of professional land surveyors, laser scanners and geospatial analysts with ample AEC industry experience who can deliver accurate and timely results.

Aerial building inspections are a lot faster and safer using drones as it saves inspectors using ladders or ropes to access rooftop areas. It’s also more efficient and cost-effective to use a drone to capture the entire roof assets, including eaves, gutters, downpipes etc. Then an inspector can conduct a desktop review safely and with confidence using 20-60 megapixel images.

Yes, at Avian our equipment includes specialised drones for use in GPS-denied environments such as underground mines. This equipment is essential when working to inspect underneath bridges and roadways where GPS satellites are unable to be located, causing the drone to behave erratically and lose control. Our drone operators are specially trained to manage small to large drones with experience in operating various payloads like thermal cameras and LiDAR scanners.

You can check out this case study wherein our team conducts a detailed asset inspection for engineering to learn more about our services.

At Avian, we worked with over a hundred AEC clients all across Australia and our stringent safety management policy incorporates industry-leading safe work methods to ensure safe aerial asset inspections:

- Comprehensive and task specific risk, job and safety assessments and SWMS

- Using enterprise-grade surveying equipment, specialised drones for asset inspection, cameras and LiDARs with stringent maintenance schedules

- Procuring the necessary CASA approvals to operate drones in and around airports, urban areas and people.

- Holding valid WorkCover insurance and PL insurance up to $20m

- Conducting comprehensive equipment maintenance schedules to reduce on-site errors and failures

- Industry-leading safe working methods for government and major civil contracts.

A member of the team will contact you soon after you book a no-obligation consultation. We then conduct a detailed job and site assessment and quotation. Sometimes we may request a site visit to ensure the job scope and complexities are understood. Based on these insights, we create a quotation, submit a proposal and schedule the aerial asset inspection schedule for your unique project requirements.