Mining surveys are the backbone of every successful operation. Yet for many teams, they’re also a source of constant pressure. The demand for precision data in harsh, unpredictable environments is immense. Surveyors and mining engineers often work against time, facing tight schedules, complex underground conditions, and, above all, safety risks.

From uneven terrain and unstable ground to limited visibility and restricted access, the challenges of mine surveying go far beyond typical project constraints. Mistakes are costly – not only in financial terms, but also in terms of human safety.

That’s why many forward-thinking mining companies are turning to 3D scanning for resource industry projects – a smarter, faster, and safer way to capture accurate spatial data.

Table of Contents

What Is 3D Laser Scanning and Why Is It Changing Mining Surveys?

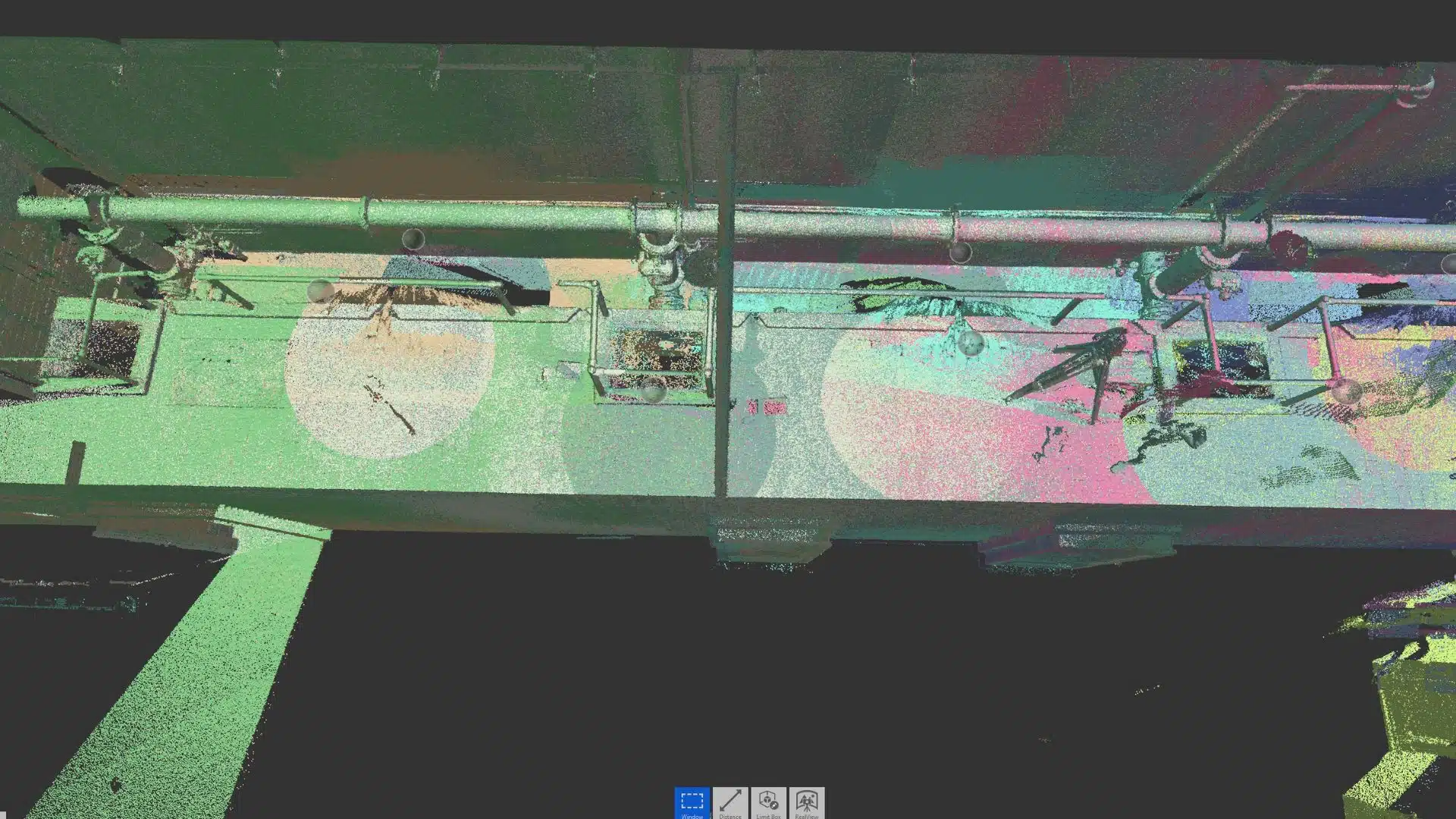

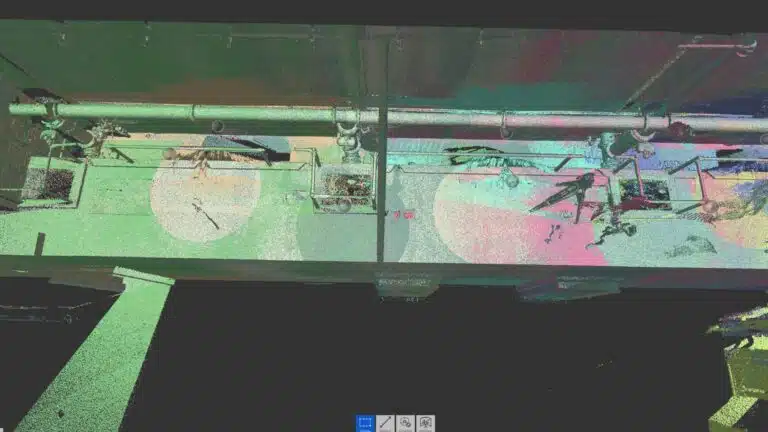

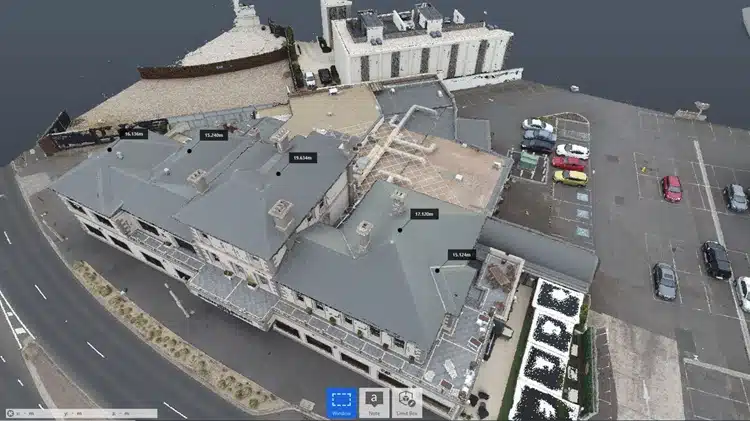

3D laser scanning is revolutionising the way mining data is captured, interpreted, and shared. Instead of relying solely on manual measurements and line-of-sight techniques, surveyors can now use laser scanners to collect millions of precise data points in just minutes. The result? A detailed 3D digital twin, known as a point cloud, that accurately represents the mine environment, both above and below ground.Traditional Survey Challenges in Mining

Before laser technology, mining surveys were often limited by:- Physical risks to personnel – entering hazardous zones to take manual readings.

- Downtime during data collection – halting operations while surveys were carried out.

- Incomplete or error-prone measurements – caused by poor visibility, restricted access, or human limitations.

How Does 3D Laser Scanning Work in Mining?

3D laser scanning works by emitting pulses of light that bounce off surrounding surfaces and return to the sensor. The scanner measures the time it takes for each pulse to return, calculating exact distances and forming a dense cloud of data points that represents the scanned area in three dimensions.What Does the Process Look Like Underground?

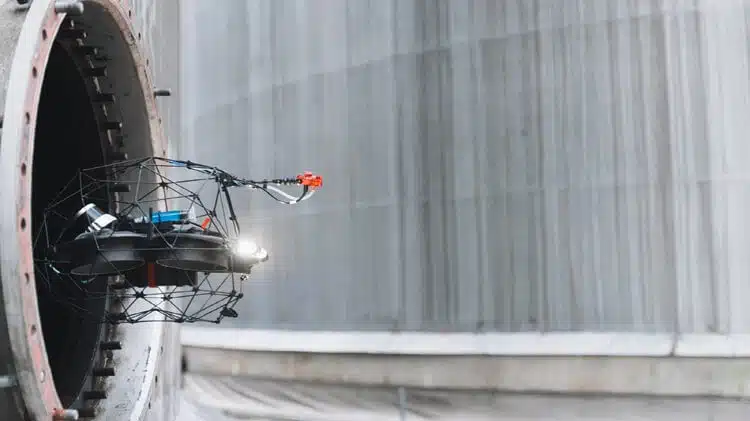

- Equipment Setup – Lightweight scanners are positioned in strategic locations, sometimes mounted on tripods or mobile rigs.

- Remote or Automated Data Capture – Scanners operate without requiring people to remain in hazardous zones.

- No-Contact Surveying – Laser beams measure distances with no need for physical contact or interference with equipment.

- Generation of Point Clouds – Millions of measurements are processed into a digital twin for analysis and decision-making.

Practical Workflows and Common Pitfalls

While the benefits of point cloud data are clear, the way architects apply the technology often determines how much time they actually save. To truly use point clouds to streamline project timelines, it helps to adopt some best practices that keep projects efficient from start to finish.

1. Commission scanning early

Engaging scanning services at the very beginning of a project ensures that everyone is working from the same “as-is” conditions. Waiting until later can mean wasted design effort if existing drawings prove inaccurate.

2. Model only what you need

Point clouds are dense and data-heavy, but that doesn’t mean every pipe or cable needs modelling in detail. Focus on the areas and features most critical to your design and coordination, and you’ll save time without losing accuracy.

3. Keep datasets organised

Large point cloud files can become overwhelming if not managed correctly. Consistent file naming, version control, and cloud hosting make collaboration smoother and reduce the risk of confusion.

4. Validate registration and accuracy

Not all point clouds are created equal. Checking tolerances and accuracy reports ensures the data is reliable before it feeds into design decisions. Skipping this step can introduce errors that ripple through the entire project.

5. Refresh data when conditions change

On active construction sites, the “as-is” environment is constantly evolving. Commissioning targeted rescans after demolition or structural changes keeps the dataset current and avoids reliance on outdated information.

Streamline Project Timelines with Point Clouds with Avian

By transforming raw data into actionable insights, Avian Australia helps architects use point clouds to streamline project timelines while maintaining the highest standards of quality and precision. Their expertise empowers professionals to streamline project timelines with point clouds, innovate with confidence, reduce risks, and deliver projects faster.

From initial 3D scanning to providing reliable point cloud for constructions and ongoing point cloud management, Avian Australia ensures that architects have the tools and support needed to achieve project success.

If you’re looking to integrate point cloud technology into your architectural practice, Avian Australia is the partner that can help you turn vision into reality.