Cutting-edge 3D laser scanning technology has revolutionised the Architecture, Engineering and Construction (AEC) industries across the world, including Australia. Architects, engineers and construction managers can incorporate accurate 3D models into their design and build workflows easily thanks to these lightweight, accurate and portable technologies. With so many advantages and features of 3D laser scanning, we often get asked – How much does 3D laser scanning cost in Australia?

With 3D laser scanning, you are able to generate millimeter-accurate 3D replicas of the as-built and natural environment and use these to develop plans, drawings, architectural models and renders. These can be used for concept designs, engineering, planning applications, presentations and more.

3D laser scanning is also used by architects for site measurements, detecting design issues, defects and as a means to resolve them throughout the project, rather than on completion. This saves time and money that would otherwise be wasted in unnecessary rework, delays or rectification.

Discover how 3D laser scanning and drone surveying technology is revolutionizing the way we conduct tree safety audits.

If you are an AEC company looking for a 3D laser scanning, this blog is for you. Here, I will be discussing some factors that affect the price and how to calculate 3D laser scanning costs for a typical project.

Table of Contents

How much does a 3D laser scanning survey cost?

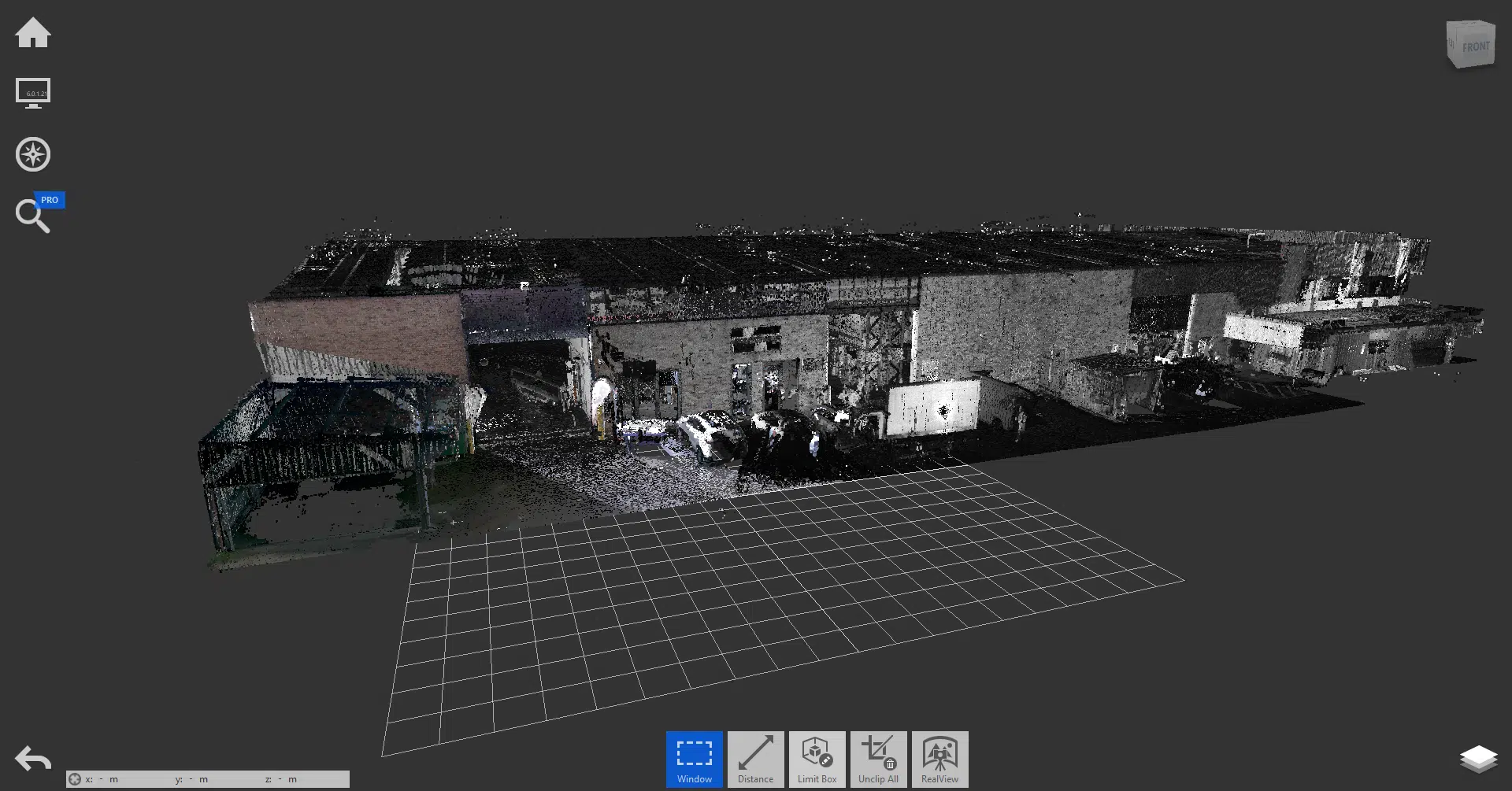

3D laser scanning costs can range from a few thousand dollars to tens of thousands and the cost is largely dependant on the size and shape of the building, structure or land area you want to scan. If the area to be scanned comprises small spaces or lots of rooms this can add time to the process, remember the laser scanner doesn’t see through objects or walls and will only record what is within line-of-sight. If the site is outdoors the size, area and elements to be captured are important as often we are required to scan the subject site and adjacent properties to record important details such as windows, powerlines, trees and buildings i.e. roof, ridges, chimneys

These are all key factors that will affect the cost. However, this can easily be determined at the briefing stage and it’s important to take a moment to explain your project needs and desired outcomes when engaging a surveyor for laser scanning.

Usually, the 3D laser scanning cost of a building interior is calculated per square meter, some surveyors will fix rates depending on the size of the project.

It’s worth noting that the cost per square meter doesn’t include additional services such as drafting plans, 3D modeling, site analysis or extra reporting.

Factors that affect 3D laser scanning cost of an AEC Project

On-location laser scanning is calculated per area or on a day rate basis. Usually, a scan project will take a day or multiple days to capture depending on the complexity of the site.

The 3D laser scanner (also known as LiDAR scanner) comes equipped with high-precision sensors that require regular maintenance and calibration. Plus, a laser scanner needs surveying to quality control the process to ensure the accuracy of the scan data.

So it shouldn’t come as a surprise that 3D scanning is more expensive than traditional surveying methods. In some cases, based on the areas to be scanned, LiDAR scanners are mounted on cars or commercial drones to carry out aerial or mobile 3D laser scanning. You can find more about the cost of drone services in this blog – How much do drone services cost in Australia?

However, the increase in cost can be offset by having a service provider like Avian who will conduct land surveys, site context analysis and other services in the same visit.

While there is nothing typical about an AEC project, due to the wide range of applications of 3D laser scanning technology, it is tricky to calculate the 3D laser scanning cost for a typical AEC project. However, I can try and summarise costs with some generic assumptions.

To answer this we can consider some factors when calculating the cost for a 3D laser scanning project.

1. Site/object dimensions

The first thing we consider is the size and shape of the space to be measured. We will need many scans to cover the space from all angles to accurately create a comprehensive 3D model with accurate dimensions.

The number of scans required depends on the size and shape of the building or structure and the type of model of laser scanner to be used. The bigger the space (such as a warehouse or large construction area) the less scans we’ll need using a laser scanner with longer range. Plus, buildings above five stories require more complex positioning of the laser scanner and can involve creative scanning positions or traffic management that adds to the costs for the 3D laser scanning survey.

The next factor we consider is the number of elements to be captured for the desired project outcomes. Basic surfaces are easier to scan like walls and roofs. But scanning steel trusses, pipelines, roads full of potholes, pits, debris etc. is more complicated. If the building comprises lots of small spaces and rooms this adds time to the process to connect each room to the scan project.

A typical scan-to-plan project starts from around $1,800 which would include the following:

- Qualified 360 scanner/camera operator

- Surveyor and total station

- Point cloud processing, registration, conversion and quality control

- File conversion to client’s preferred formats

- Delivery of Data via a secure cloud link to as hard copy

- On Request – 2D Floor Plans drafted from point cloud in DWG/PDF

- On Request – Feature and Level survey, Title Boundary survey, Architectural Set

- On Request – Web portal for 3D visualisation and team collaboration

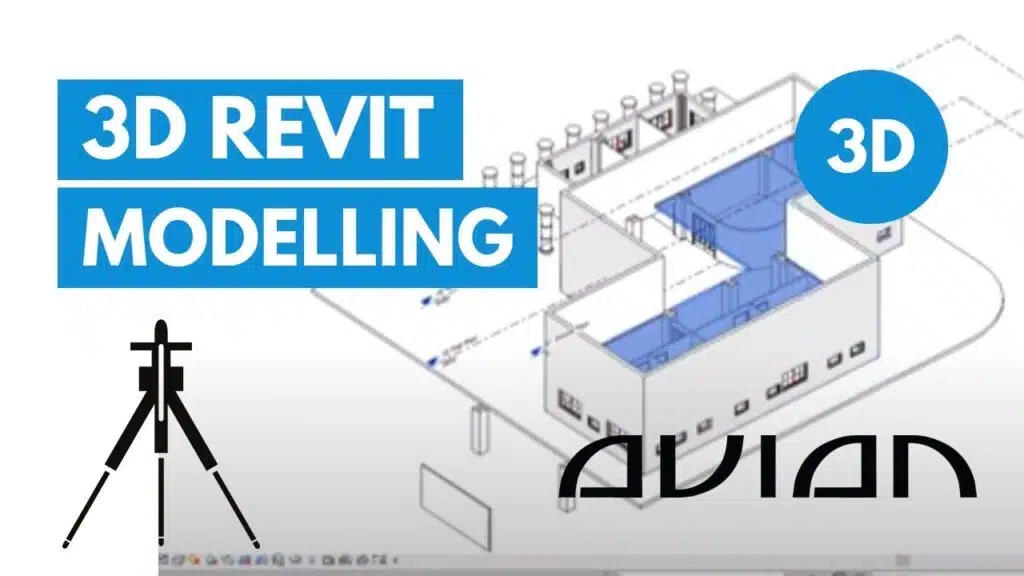

A typical scan-to-model project starts from around $3500 which would include the following:

- Qualified 360 scanner/camera operator

- Surveying total station

- Point cloud processing, registration, conversion and quality control

- File conversion to client’s preferred formats

- 3D Revit Model generation RVT from point cloud

- Delivery of Data via a secure cloud link

- On Request – 2D Floor Plans/Drawings, Elevations, Sections, Reflected Ceiling Plans, in Revit, AutoCAD (rvt, dwg or pdf)

- On Request – Feature and Level Survey to AHD

- On Request – Web portal for 3D visualisation and team collaboration

Check out our 3D Laser Scanning Packages

2. 3D laser scanning technology

There are different types of 3D scanning technologies, each with their fair share of pros and cons.

Selecting the right 3D scanner and scanning methodology ensures that you get the best result from the laser scanning without extra hassles.

So, how do we select the right 3D scanner and scanning methodology for your project? As always, the devil lies in the details!

For instance, if you want to scan a warehouse building with a small number of adjoining offices and rooms then a scanner with lower range and wider scan range will be suitable. This would save on cost and would cover the entire building with one surveyor with a scanner and surveying equipment to capture the project.

However, if you want to scan a road bridge with complex steelwork we need to use a scanner with longer range, higher fidelity and more dense point cloud data. This adds cost in the form of more staff with a more complex scanning methodology plus a higher data load to manage and manipulate.

A 3D Virtual Tour of a site starts from $1500 and this typically covers the following:

- Commute expenses up to 30km from major CBD area of any city in Australia.

- Qualified 360 scanner/camera operator fees

- Virtual tour processing, hosting, annotations and quality control

- File conversion and hosted via secure weblink

- On Request – 2D Floor Plans/Drawings, Elevations, Sections, Roof Plans, in Revit, AutoCAD (rvt, dwg or pdf)

- 3D Revit Model (.rvt) from point cloud

- Client logo and branding on the end output deliverable files

- Optional quantities and schedule of materials

- On Request – Defect annotations and icons within virtual tour

- Web hosted portal for 3D visualisation and team collaboration

Here are some more explanation of the process of 3D laser scanning you should know about:

3. Structured light scanning

Structured 3D scanning involves projecting multiple light patterns on the object to measure its dimensions. To take one shot, the scanner and camera has to move around the object covering it from multiple angles.

This process is a little time consuming and has a relatively smaller range of vision. Also structured lighting is not ideal for scanning highly reflective surfaces like mirrors. This is because the laser light bounces back from the object creating noise in the point cloud that has to be removed.

However, this type of scanning ensures greater accuracy and works well for smaller objects.

4. Laser scanning

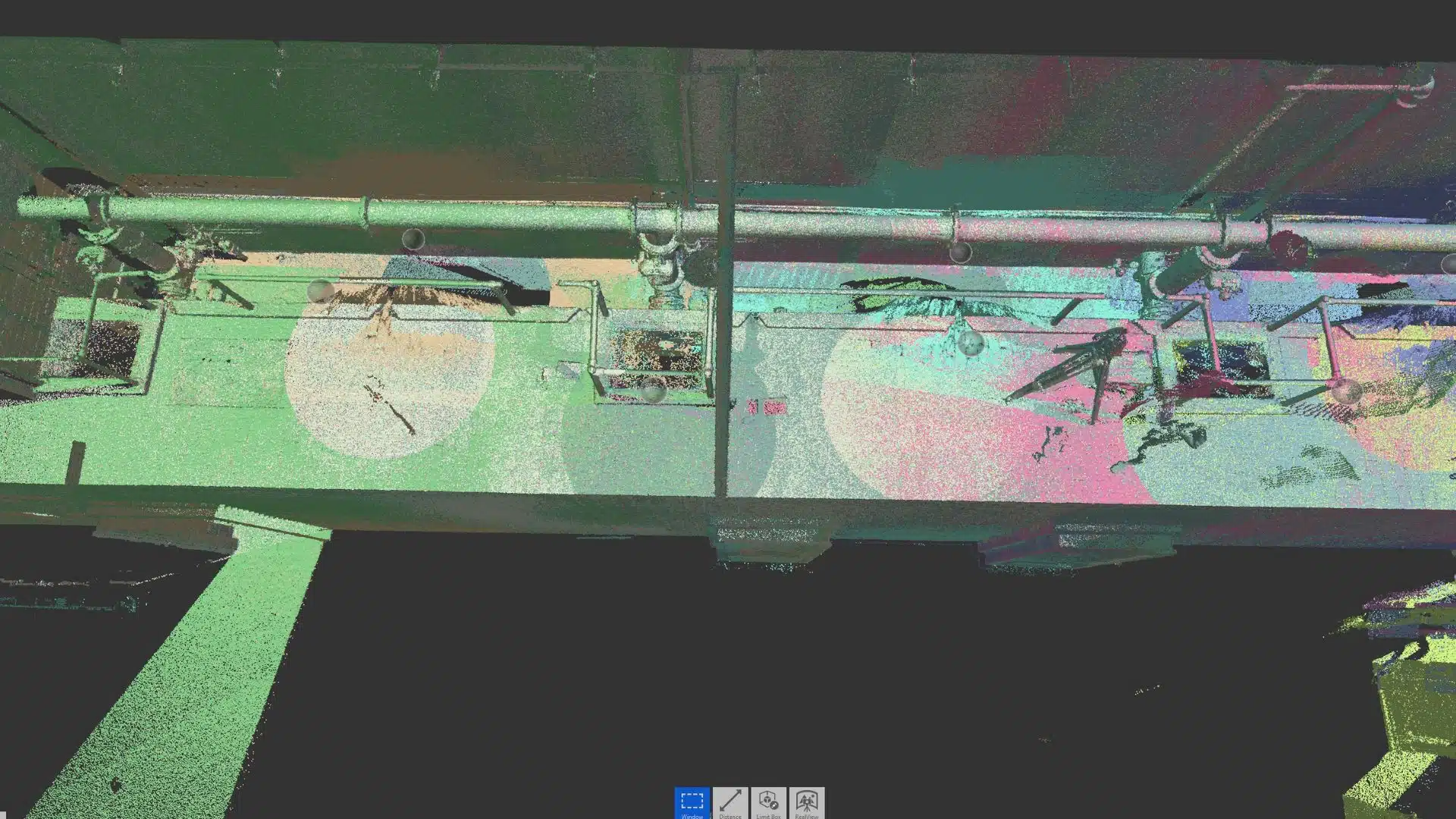

Laser scanning uses millions of lines of laser light to scan the area or object and measures the time to return the laser beam then saves it as data points into a 3D replication called a point cloud.

These point clouds are exported and digitally converted to 3D replication of the space or object using CAD or BIM software.

Laser scanning is ideal for larger spaces or objects where you need to measure with accuracy that would otherwise take a long time to first measure and then draw into a 2D plan or 3D model.

Laser scanners also perform millions of precise measurements in all directions at a faster rate without human errors.

5. How long does 3D laser scanning take?

Laser scanners work a lot faster when compared to standard surveying methods. For instance, scanning a 1000 sq ft room manually will take a couple of days, with a laser scanner it will take half a day.

3D laser scanners work both indoors and outdoors, in pits and confined spaces, in roof spaces and in total darkness. The longer it takes to perform the 3D laser scanning survey on a specific site, the higher the cost of the project.

For more details on cost and the myriad of applications for laser scanning, contact our surveying professionals today.

At Avian Australia, we believe in providing data-driven business solutions tailored to your unique project needs. Our industry specific knowledge and expertise will ensure a tailored solution that delivers benefits and results above expectations.

Book in a no obligation consultation with the team at Avian Australia to discuss a customised laser scanning plan for your project.