The Architecture, Construction, and Engineering (AEC ) industries have witnessed a revolutionary shift in site inspection methodologies, evolving from manual, time-consuming processes to the adoption of advanced technological solutions. Among these, 360 Site Inspection Surveys have emerged as a forefront innovation, redefining remote construction site management.

Leveraging immersive photography and panoramic imaging, these surveys facilitate comprehensive site evaluations without the physical presence of inspectors, thus significantly reducing time and costs associated with traditional inspections.

This blog aims to delve into the nuances of 360 Reality Capture and its role in Virtual Site Inspections, highlighting their pivotal role in augmenting construction risk management strategies for AEC professionals across Australia.

By embracing this cutting-edge technology, industry players can not only enhance operational efficiency but also mitigate potential project risks more effectively and easily share and communicate these risks.

Through this exploration, we will reference industry data and examples to underscore the transformative impact of 360 Virtual Inspections in the contemporary construction landscape.

Table of Contents

1. What is a 360 Site Inspection Survey?

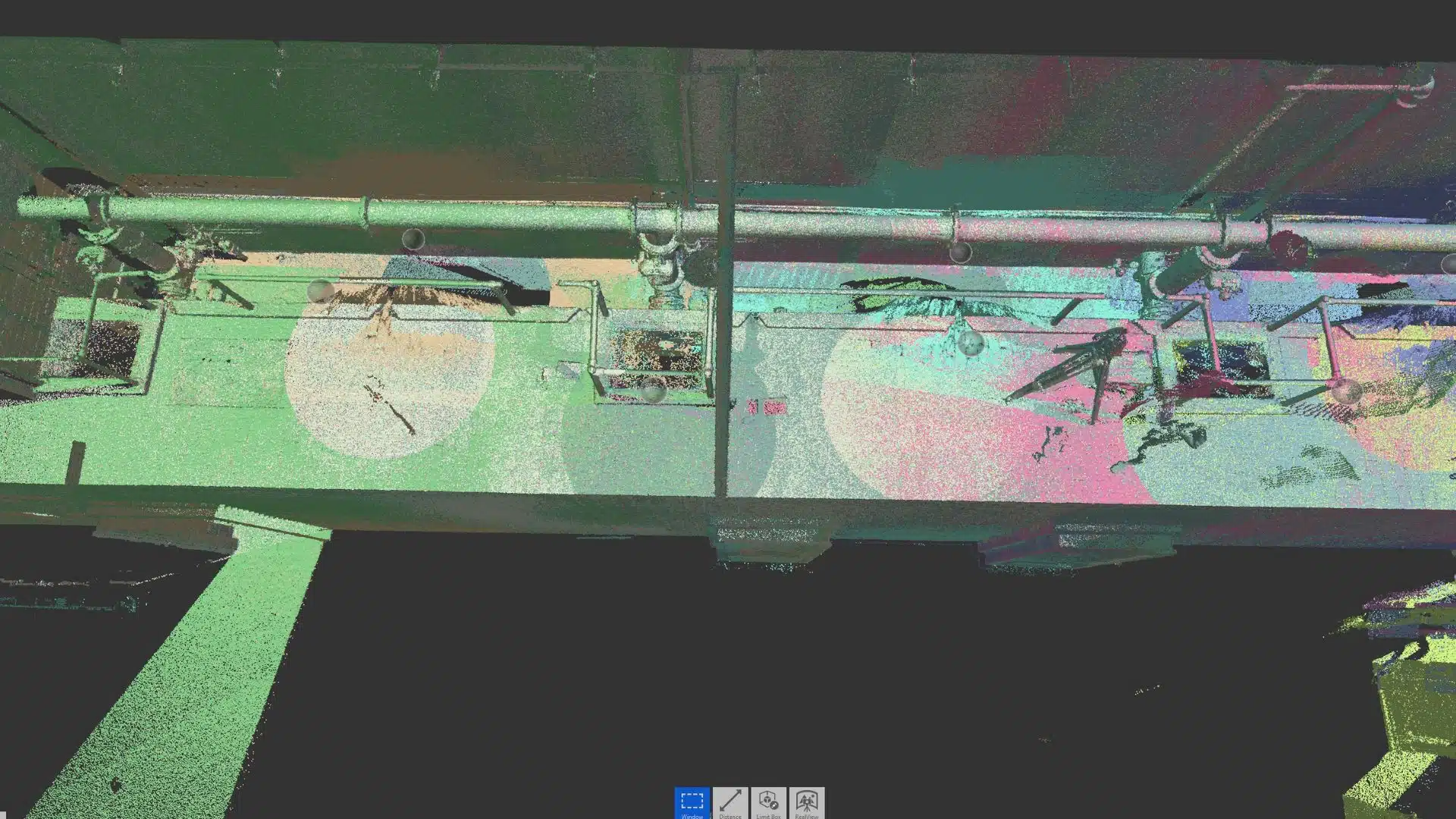

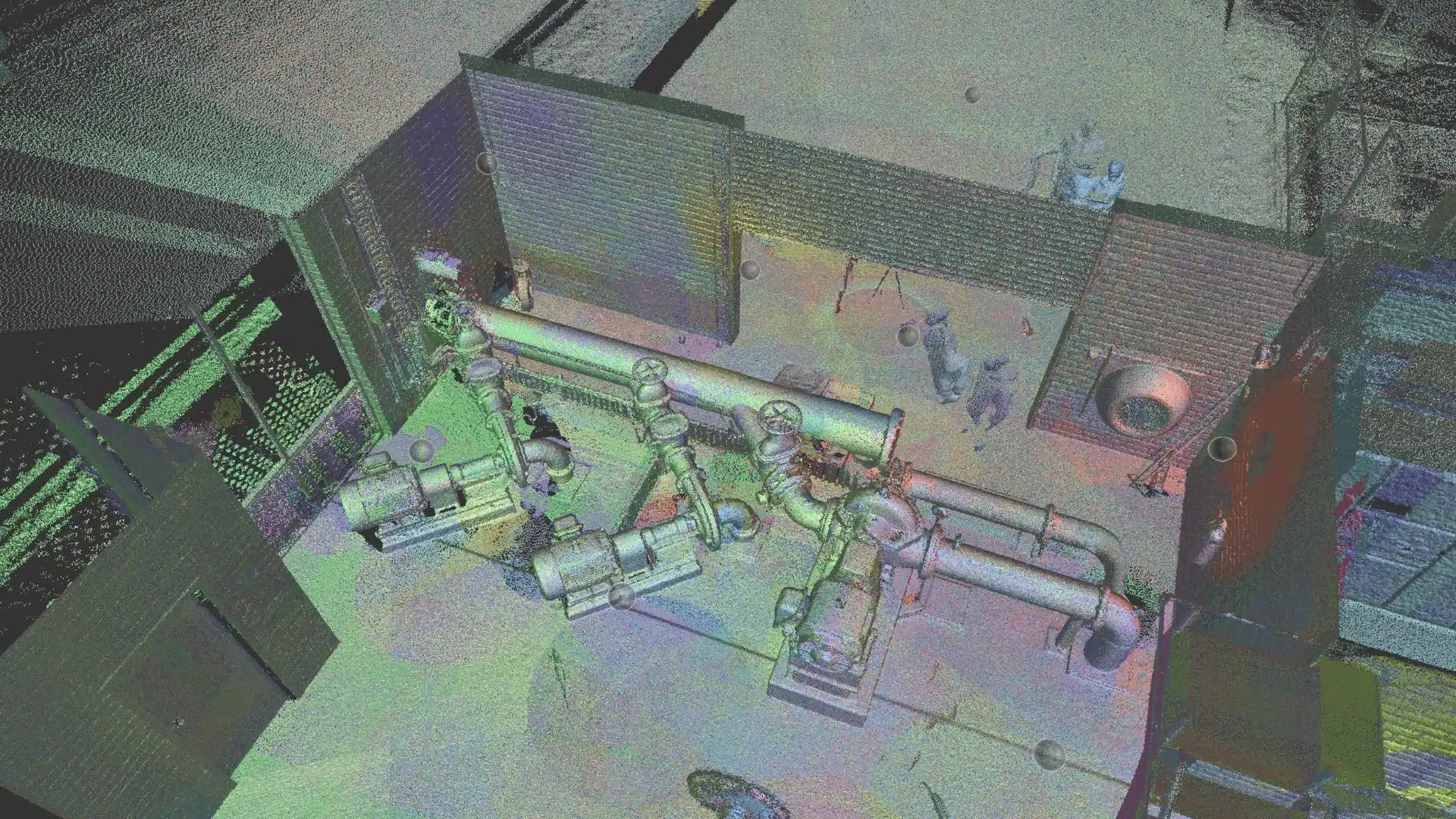

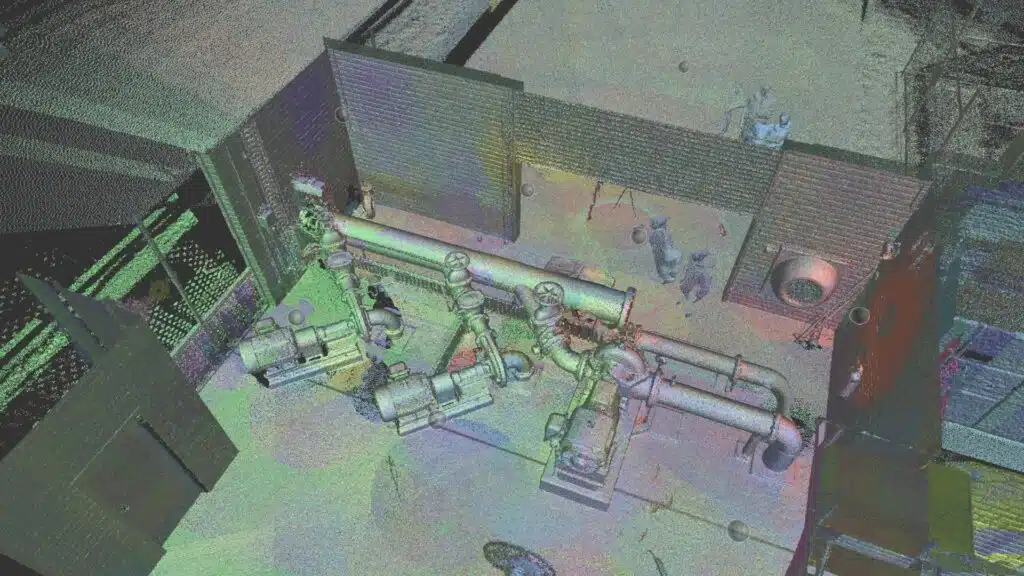

Reality capture is like having a digital twin for your construction site. It’s the process of meticulously recording and documenting the physical world using cutting-edge technologies such as 3D laser scanning, 360 photography, photogrammetry and drones. Imagine capturing the essence and complexities of your job site in high-resolution detail, creating a virtual replica that mirrors reality, complete with site issues and risks. The technology often utilises aerial data captured by drones, selected from reliable inspection drones tailored for construction and infrastructure projects.

In the dynamic realm of construction, 360 Site Inspection Surveys blend cutting-edge technology with practicality, allowing project teams and stakeholders to inspect, analyse, and manage projects remotely and in their own time. Let’s break it down:

A. Technology Trio behind 360 Reality Capture

The magic lies in the triumvirate of Laser Scanners, Photogrammetry and 360 Photography. These technologies work in harmony to capture the site from every angle, creating a digital twin that mirrors reality.

B. Transformative Power of 360 Site Inspections

- Panoramic Imagery – Imagine standing at the heart of your site, capturing the entire scene in a 360-degree sweep. These panoramic images serve as the canvas for insights and context.

- Annotated Points of Interest – Overlay annotations directly onto the imagery—defects, safety hazards, milestones. It’s like leaving digital breadcrumbs for stakeholders and project teams.

- Integration with Project Management Software: Seamlessly connect the visual data to project management platforms. Inspections, progress tracking, and issue resolution become a cohesive dance.

In a nutshell, 360 Virtual Site Inspection Surveys empower builders and construction management to see beyond physical boundaries, making informed decisions without stepping foot on-site.

2. Advantages of 360 Site Inspections for Construction Professionals

360 Site Inspections are transforming the landscapes of the AEC sectors by offering a suite of benefits that propel efficiency, enhance documentation, foster collaboration, and streamline risk management.

These advantages have profound implications for construction professionals, reshaping traditional methodologies into more dynamic, efficient, and risk-averse processes.

A. Time and Cost Efficiency

Traditional site inspections necessitate frequent travel, consuming valuable time and resources. 360 Site Inspections eliminate the need for physical presence on-site, offering a remote yet comprehensive view of the project. This not only saves on travel expenses but also accelerates the inspection process, allowing professionals to allocate their time to other critical tasks.

The ability to conduct multiple site reviews without leaving the office underscores a significant leap in operational efficiency and cost-effectiveness. Site visits can be planned more effectively when the need arises.

B. Comprehensive Documentation

The creation of a digital twin through 360 Site Inspections offers a detailed and immersive representation of the site, available for reference at any point in time. This centralization of project data is invaluable for risk analysis and issue management, providing a holistic view of the project lifecycle and enabling more informed decision-making. It ensures that all stakeholders have access to the same information, reducing discrepancies and misunderstandings.

Different project stakeholders require different pieces of the puzzle, but they all need to be working on the same information and towards completing the same puzzle picture.

C. Enhanced Collaboration

By facilitating remote access to the site for all project stakeholders, 360 Site Inspections break down geographical barriers, enhancing collaboration. Architects, engineers, project managers, and clients can review the project’s progress in real-time, from anywhere in the world.

This synchronous communication fosters a more cohesive project management approach, ensuring that all parties are aligned with the project’s objectives and timelines.

D. Immediate Issue Identification

The immersive and detailed nature of 360 Site Inspections allows for the early detection of potential issues, enabling proactive risk management. This immediate visibility into project risks is critical for avoiding costly mistakes and delays.

By identifying and addressing issues early, construction professionals can mitigate risks more effectively, ensuring project delivery is on time and within budget.

Case studies across the AEC industries demonstrate the tangible benefits of 360 Virtual Site Inspections. According to a research paper published in the Journal of Construction Engineering and Management, reality capture technologies facilitate a better understanding of project requirements, constraints, and complexities. They can help with site context, clash detection, resource planning and improve overall budget and cost management.

3. Integrating 360 Virtual Site Inspections into Construction Risk Management

Let’s explore their transformative impact on Construction project risk management and compliance:

A. Enhanced Project Visualization with BIM 360

BIM 360, a robust project management platform, enhances project visualisation by integrating 360-degree imagery. Stakeholders virtually walk through sites, identifying risks and deviations. BIM 360 acts as a digital hub, bringing together all project stakeholders—architects, engineers, contractors, and owners. It acts as a unified repository as It centralises design documents, floor plans, 3D models, and project data in the cloud.

B. Integration Strategies

- Seamless Integration – Embed 360-degree photos into existing risk management frameworks. Link inspections to risk registers and action plans.

- Risk Minimisation – Real-time visual data allows proactive risk mitigation, preventing costly surprises down the road.

- Automated Reporting – Generate concise reports with annotated images, streamlining communication and decision-making.

4. The Future of Virtual Reality in Remote Site Inspections

The future of site inspections in the Architecture, Engineering, and Construction (AEC) industries is poised for transformative change, driven by the integration of Augmented Reality (AR) and Virtual Reality (VR) with AI-driven analytics.

These advancements promise to further enhance the capabilities of 360 Site Inspections, making them more interactive, insightful, and immersive.

CARELL Greece has managed to be the first company in the Ship repair & Maritime Engineering sector to introduce and implement the new AR/ VR Technology of Microsoft Hololens 2 for remote inspections on board ships.

The advantages for the use of the remote inspections can also be found in Industrial Engineering (factories, refineries) as well as for our Hydrogen Engineering fabrications and after sales technical assistance.

The Bottom Line

With the ability to overlay real-time data and predictive analytics onto virtual models, professionals can anticipate and mitigate risks with unprecedented precision. Additionally, the global scalability of these technologies will enable seamless international collaboration, allowing project teams across different geographies to work together more effectively.

This evolution signifies a significant leap towards more efficient, accurate, and collaborative construction project management and risk assessment, heralding a new era of innovation in the AEC industries.

Empowering your projects with cutting-edge technology, Avian Australia ensures unparalleled accuracy and efficiency in every inspection. From detailed 3D scans to immersive virtual tours, our reality capture solutions revolutionize the way you perceive and manage your project sites.

Experience the future of site inspections today. Reach out to Avian Australia and elevate your projects across Australia.