Land surveying and construction site inspection are perhaps the greatest challenges that a contractor or onsite engineer faces when working on a construction project.

Sometimes, it is simply not possible to manually measure and map the construction site – a practice that a lot of construction still stubbornly holds onto.

In larger projects conventional land surveying methods are laborious, require a lot of resources and often stretch up to weeks on end depending on the size of the project. Also, manual inspections and assessments are prone to human errors, which can impact the progress of the project.

Therefore, it is extremely important that construction agencies stay updated about the latest technologies like 3D laser scanning in construction land surveying. 3D laser scanning in construction is one of the fastest growing technologies that has completely reinvented site inspections and conventional surveying.

Table of Contents

Many construction companies are slowly coming around, incorporating new technologies such as digital sensors, 3D printing, drone tech, app integrations, cloud computing etc.

The use of 3D laser scanning in construction has become increasingly popular over the past few years, helping engineers, architects and contractors with surveying, digital mapping and 3D modelling.

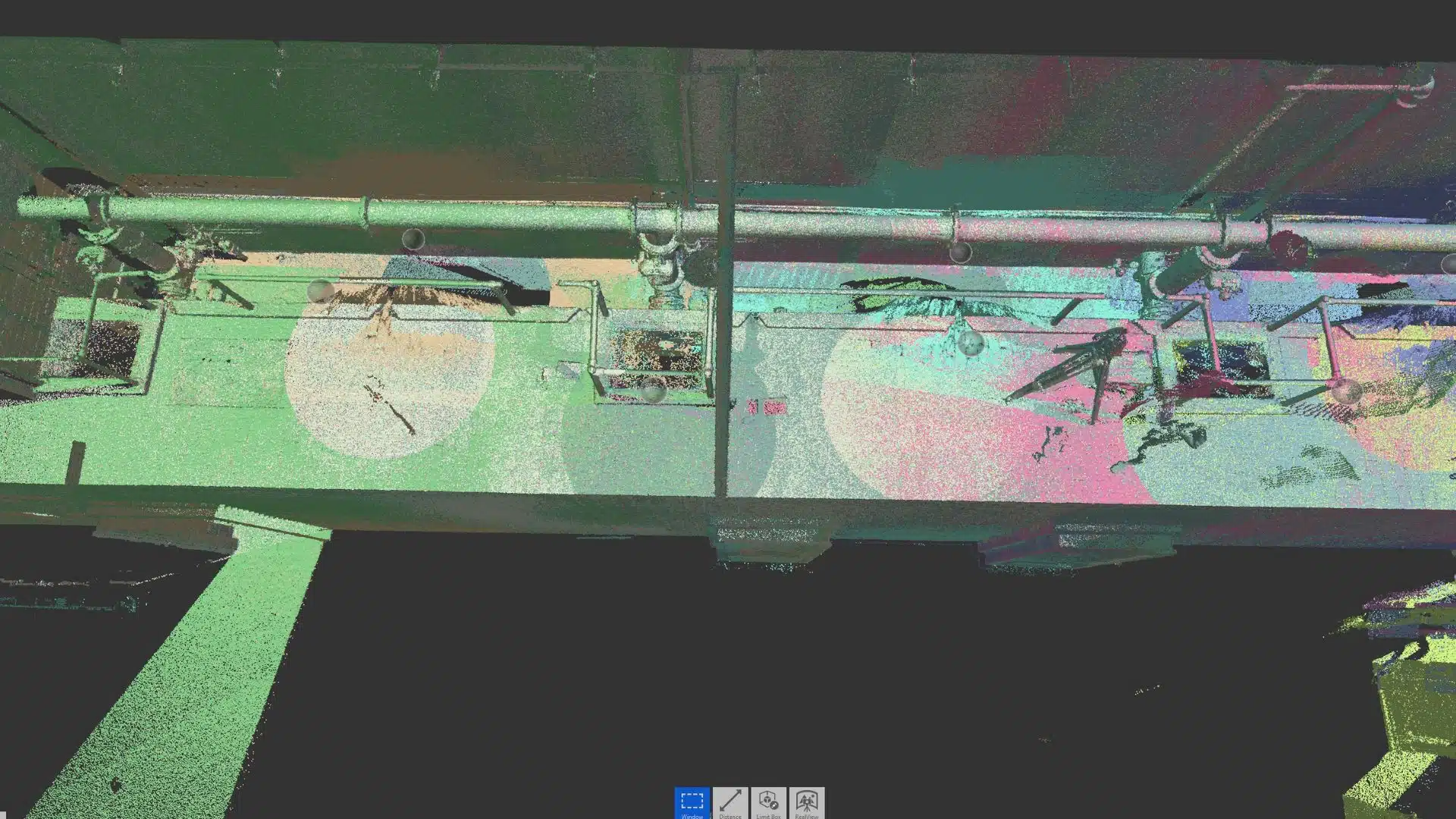

3D laser scanners are also known as LiDAR scanners that capture site measurements and save it as point cloud data. This data is then used to create 3D sitemaps and models that improve project design and reduce on-site errors.

Read on to know all about 3D laser scanning companies are reinventing the construction industry.

What is 3D laser Scanning?

3D laser scanning in construction captures as built structures, objects or wide spaces such as quarries, construction sites and buildings using laser light. LiDAR scanners gather millions of measurements per second and save them as a point cloud which are then used to replicate the scanned environment.

Depending on your surveying needs, the LiDAR scanners can scan objects up to several hundred meters! Also, laser scanners are far more accurate than your average drones. The output data thus collected can have an accuracy of 10mm or less, capturing thousands point cloud points per second even from hundreds of meters away.

3D Laser Scanning and Digital Visualisation

In case the building or construction site is too large to be surveyed in a single scan, you can use 3D laser scanners to scan the site from multiple positions. These different scans are not saved as different point cloud images but combined to create a single point cloud and 3D model.

The 3D point cloud image thus generated is then exported to a CAD or BIM application model for drafting into 2D drawings, plans or 3D models.

Experience the next level of tree safety assessments with the integration of 3D laser scanning and 3D visualisation technologies for conducting remote tree assessments.

CAD or computer aided design converts point cloud site data into 2D maps and 3D models using a complex network of algorithms supporting a modelling workflow. These 2D CAD drawings or 3D models are crucial to create concept models, designs and working prototypes.

3D modelling and digital visualisation makes your design plan “sellable”. It helps architects and engineers create attractive presentations using these models to get the designs approved and attract more investors to get on board with the project.

Implementing 3D Laser Scanning in Construction Industry

Not every construction site is the same. Each project has its unique needs and varying complexities. For instance, in one building construction project, the manager might face difficulty monitoring on-site activities and staying on schedule. In another case, the building contractor can have trouble cutting costs and sticking to the budget.

Irrespective of the issues, using 3D laser scanning in construction can help you resolve all these conflicts and more. Laser scanners are used in all types of construction projects – be it civil, residential or commercial.

You can use 3D scanners for scanning large sites, interiors, industrial buildings, complex machinery, pipework and HVAC systems.

A common problem that surveyors face with 3D scanning is the point cloud data takes a lot of memory space, extending to hundreds of gigabytes. It takes a lot of time to transfer, manage and manipulate this data, especially if you don’t have the right data management processes and software.

However, I highly recommend 3D laser scanning solutions to contractors who have to work on tight schedules and need to work with accurate site measurements and information. Often the client requests as-built drawings before and after the project completion and laser scanning is essential for this requirement.The time taken by laser scanners to capture a building or site is at least 50% less when compared with traditional surveying methods.

For this reason, 3D laser scanning has become a popular choice for construction projects such as commercial projects, worksites, steel fabrication, machinery installations, road construction projects and more.

You can get a good estimate of 3D laser scanning cost in our featured blog – How much does 3D laser scanning cost in Australia?

Beyond 3d laser scanning, drones are also popularly used to promote projects to prospective investors and buyers. Following is a project profile video created for TZ Constructions at Barber Ave, Penrith, Victoria.

Benefits of 3D Laser Scanning

While initially seeming more expensive, 3D laser scanning in construction offers time-saving and cost-effective solutions. Also, with 3D scanning solutions, you need a surveying or 3D modelling expertise to export, process and convert the point cloud image to precision 3D models.

Don’t let that deter you though, the benefits of 3D laser scanning far outweigh the costs.

Here are some advantages of LiDAR or laser scanning.

Better design and project planning

The 3D models created using point cloud data can significantly improve the project design. It allows architects and site engineers to better visualize how the building, paths, roadway or any other construction looks on ground and in relation to each other.

We build and live in 3D yet still continue to draft and present our ideas in 2D!

The accurate dimensions help determine the basic shape, size and structure of the project. 3D scanners also help designers detect errors in the design and resolve them in the conceptual stage.

This saves a lot of time, reduces waste and eliminates the need for costly rectification and rework.

Improved worksite safety

With laser scanning, surveyors can reach spaces on the construction site that would have been otherwise inaccessible for workers. You don’t have to risk the safety of workers, making them climb rooftops, inside tight roof cavities or get inside pipelines.

With LiDAR scanners you can inspect rooftops, get inside pipelines, measure tower structures, scan bridges etc. This type of laser scanning assists engineers detect structural damages and confidently plan repairs and maintenance.

Time saving and cost effective

3D scanners take almost half the time needed to survey a site when compared to manual surveying. Also, with laser scanning you can reduce the total project costs by 7%.

3D laser scanning is an easy integration into your project and existing workflow.

Hire the best drone professionals

Avian Australia specializes in 3D laser scanning in construction, providing top-tier land surveying and site inspection services. We can take care of all your laser scanning, site inspection and surveying needs. Our team is expertly trained and experienced to manage your 3D laser scanning project needs.

Book an appointment today and we’ll take care of the rest.